Your hydraulic cylinders are an essential piece of equipment in your business. It helps you move and control heavy loads, so it’s important to keep it in good condition. By following a few simple tips, you can prolong the life of your Hydraulic Cylinders and avoid costly repairs. This article will show you how to maintain your hydraulic cylinder for longer life.

What is a hydraulic cylinder?

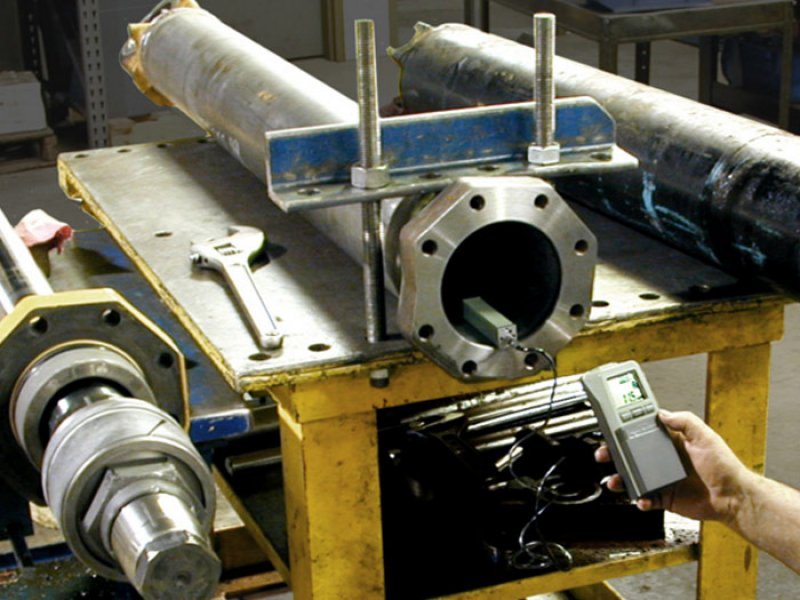

A hydraulic cylinder is an important part of many machines and vehicles. It converts energy from a fluid into linear motion. The hydraulic cylinder gets its own Hydraulic Power Packs from pressurised fluid, which is used to push or pull the piston inside the cylinder. This piston is connected to the piston rod, which transfers the linear motion to whatever you’re using the hydraulic cylinder for.

What are the different types of hydraulic cylinders?

There are many types of hydraulic cylinders on the market, each with its own unique benefits and drawbacks. Some of the most common types of hydraulic cylinders are tie-rod cylinders, welded body cylinders, and telescopic cylinders.

Tie-rod cylinders are the simplest type of cylinder and consist of a cylindrical barrel, a piston rod, and two end caps.

The barrel is typically made from steel tubing and is either welded or machined to form the end caps. The piston rod is usually made from solid steel bar stock and is either threaded or drilled and tapped to accept a threaded connection to the hydraulic valve.

Welded body cylinders are similar to tie-rod cylinders, but the barrel and end caps are permanently welded together.

How do hydraulic cylinders work?

Hydraulic cylinders convert the linear motion of a piston into rotational or oscillatory motion. The main components are the barrel, piston, rod, and seals. The rod transfers force between the piston and barrel, and the seals keep the oil inside and outside of the cylinder. The barrel is typically made from steel or aluminium, while the piston can be made from a variety of materials such as brass, stainless steel, or composites.

What are the most common problems with hydraulic cylinders?

The four most common problems in Industrial areas with hydraulic cylinders are leakage, corrosion, contamination, and cavitation. In most cases, these problems are the result of either poor maintenance or incorrect installation. If you’re not sure how to properly maintain your hydraulic cylinder, it’s best to consult with a professional. That way, you can be sure that your cylinder is in good condition and will last for a long time.

How can you prevent hydraulic cylinder problems?

Here are a few key things you can do to help prevent problems with your hydraulic cylinder:

-Keep the cylinder oiled and clean

-Inspect the seals regularly for signs of wear or damage

-Make sure all fittings and connectors are tightly fastened and properly aligned

-Avoid overloading or excessive use of the cylinder

If you follow these simple tips, you’ll be able to keep your hydraulic cylinder in good condition and extend its lifespan.

Conclusion:

Hydraulic cylinder is an essential part of many machines and vehicles. By following a few simple maintenance tips, you can help to extend the life of your hydraulic cylinders and avoid costly repairs.